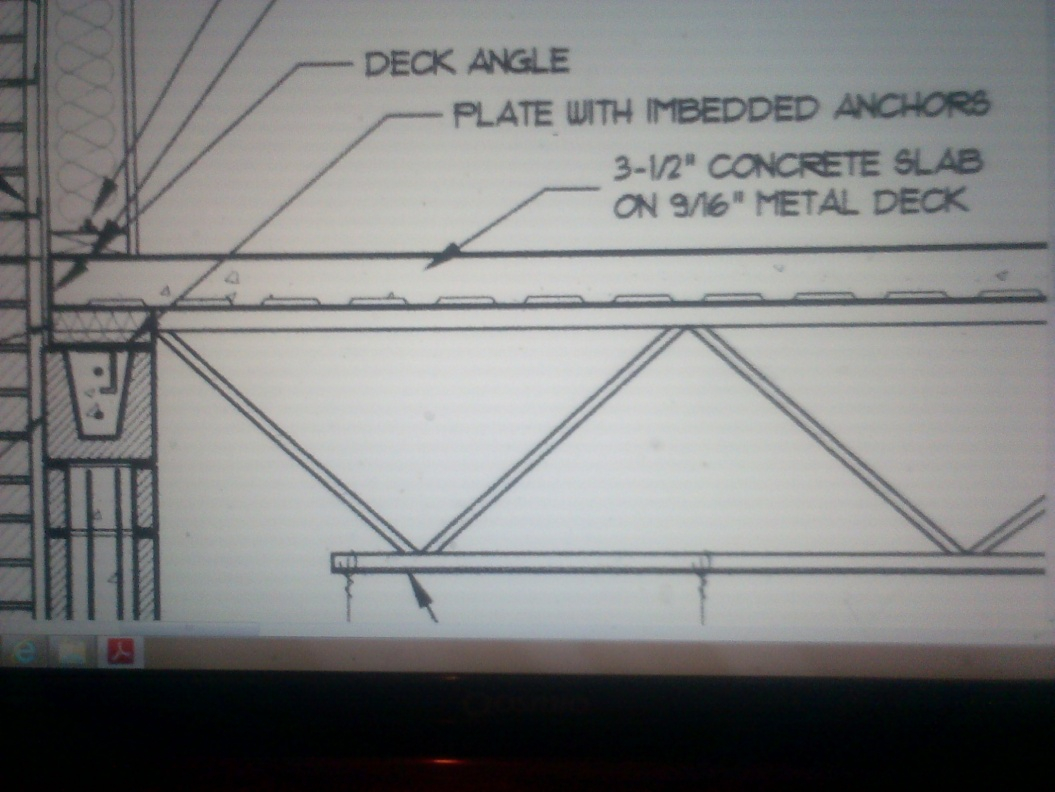

Concrete On Elevated Deck Concrete Paving Contractor Talk within dimensions 1055 X 792

Concrete On Elevated Deck Concrete Paving Contractor Talk within dimensions 1055 X 792Pour Elevated Concrete Deck – Let’s begin first we must appraise the area would it be a turf or concrete base beneath the decking a turf base will must be dug off and membrane put beneath the decking you’ll be able to and will put membrane under any decking project to stop any weeds penetrating through, where would be the damp course levels even as are afraid when above the damp course ideally when needs to be two bricks below the damp course. And can there be any drain access points beneath the decking as these will require an exclusive decking drain cover. Always remember the decking boards go horizontal along the house. Always remember decking higher that 1.2m off the ground level will require planning permission

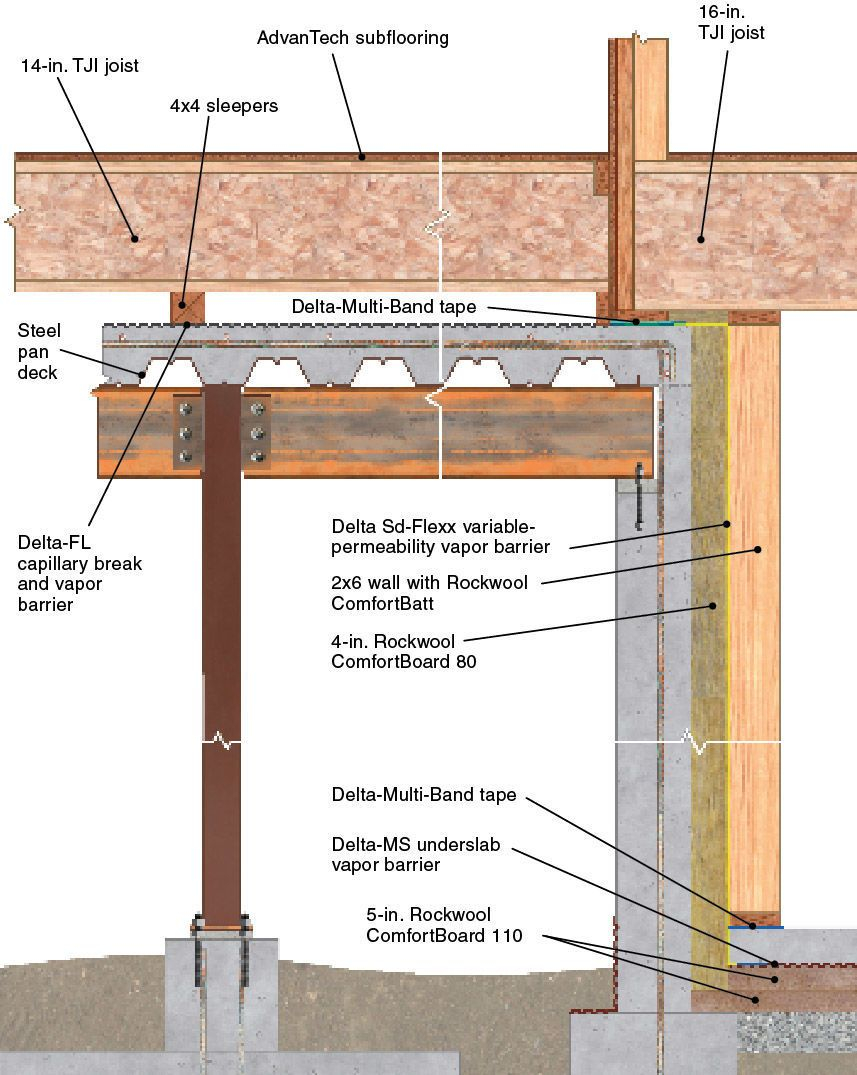

Start With A Steel Deck Fine Homebuilding Foundations In 2019 throughout proportions 857 X 1075

Start With A Steel Deck Fine Homebuilding Foundations In 2019 throughout proportions 857 X 1075Now we’ve assessed these factors they’re going to decide the height of when and then any special requirements that must be incorporated in the decking project. Estimation of materials first appraise the area of the decking i.e 4.8m x 4.8m = 23.04sq meters. Then utilize this equation to calculate the decking boards needed 4800mm / 140mm (deck board width which are 4.8m long) = 35 decking boards. Add a little for cuts and edges that must be filled in. Then calculate the strain bearing supports (4 x 2 pressure treated CLS) 4800 / 600 = 8 This the volume of horizontal 4 x 2 pieces needed for your internal structure of the decking as well as the outside of the frame i.e. 4800 x 4 = 19.2m + (8 x 4800) = 58m of four x 2. Add some for your cross member struts and positioning pegs (banged and concreted if needed in the ground) about 3 or 4 4.8m lengths should suffice.

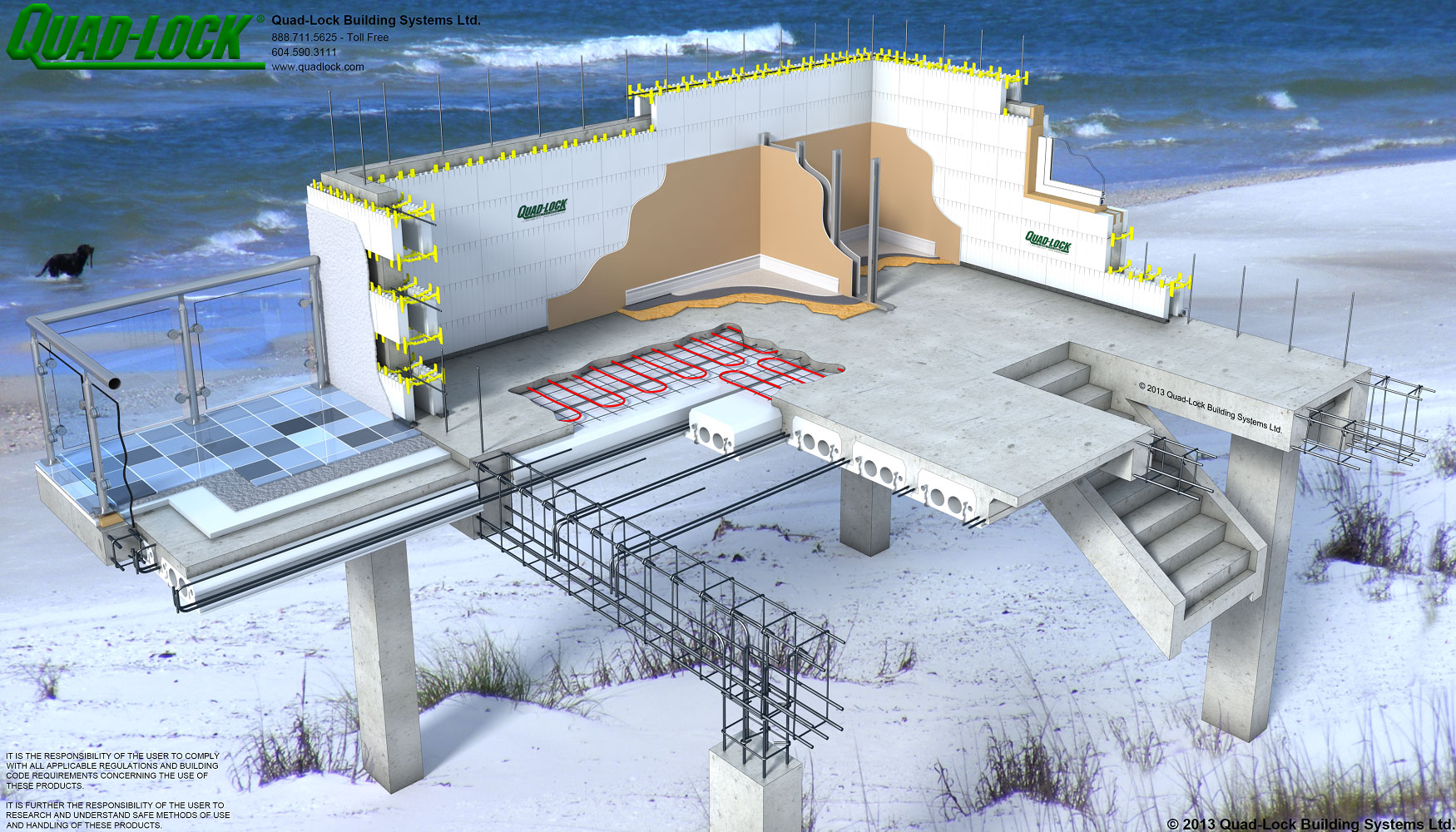

Quad Deck Insulated Concrete Forms For Floors And Roofs regarding dimensions 1750 X 1000

Quad Deck Insulated Concrete Forms For Floors And Roofs regarding dimensions 1750 X 1000Establishing the frame this should be done near or as close towards the position of the final deck. Start by cutting the ends of the required wood square this might help with all the construction of the frame always cut the pieces of wood the same length because frame will not be square in the event the wood is of lengths. Then join the corners of the frame by piloting the holes for your 4 inch screws to be screwed into wood. Once this is achieved you need to get the frame square, having an engineers square stick it in one corner and move until square. Then screw a batten inside corner to carry the corner square make this happen for all those corners. Then measure internally in the horizontal of the frame the place that the load bearers are getting divide this measurement by 600mm this will provide you with an identical spacing for your struts. Next screw theses set up it really is easier to place a length of wood beneath the frame while achieving this to find the edges in order to meet. Once this is achieved appraise the cross member struts around three feet is approximately right for your spacing of these. They go vertically along when frame stepping out then directly into allow for screwing.

Releasing Heavy Loads On Elevated Concrete With Efco Deck Shoring inside measurements 1280 X 720

Releasing Heavy Loads On Elevated Concrete With Efco Deck Shoring inside measurements 1280 X 720Ranking of when, get when into position with all the help of the friend. Then start inside highest corner of when and bang a bit of cut 4 x 2 (depending around the height of when cut accordingly) in the ground having a large sledge hammer. Once done lift when into position and screw together having a 4 inch screw. Now work along when towards the next horizontal corner lifts the corner therefore the frame is level and do the same. Now work along the front have a slight lean away in the house or ensure whichever way the boards are running tip when therefore the water runs out of the surface. Then work your way across when ensuring that that any some weakness is based on banging a piece of four x 2 in the ground beneath it. Once this is achieved test the strength by walking along the struts showing any some weakness no problem an excessive amount of because decking boards will strengthen the decking after they are fixed towards the frame.

Steel Beams And A Metal Pan Deck Fine Homebuilding with measurements 1200 X 900

Steel Beams And A Metal Pan Deck Fine Homebuilding with measurements 1200 X 900Nowadays we cut and fit in the decking boards towards the frame. Make sure every one of the edges of the decking are cut square before cutting towards the correct length. This will aid construction and overall Finnish of the decking project. Start having a full length of decking ensuring that the conclusion meets the frame or cut the board towards the nearest beam and connect the board having a Paslode nail gun using 50mm nails or pilot and countersink holes and screw the boards screwing is way better lasting but nailing is faster and easier. Work along when spacing having a 5mm nail banged into a piece of four x 2, this will ensure how the gap remains the same. Always remember to stagger the joints of the decking almost every other board therefore the joints blend in the decking. Once you decking boards are fitted then fit any surrounding decking boards towards the edges to pay up any of the frame work and look for virtually any boards who have splinters and sand these down if you’ll be able to.