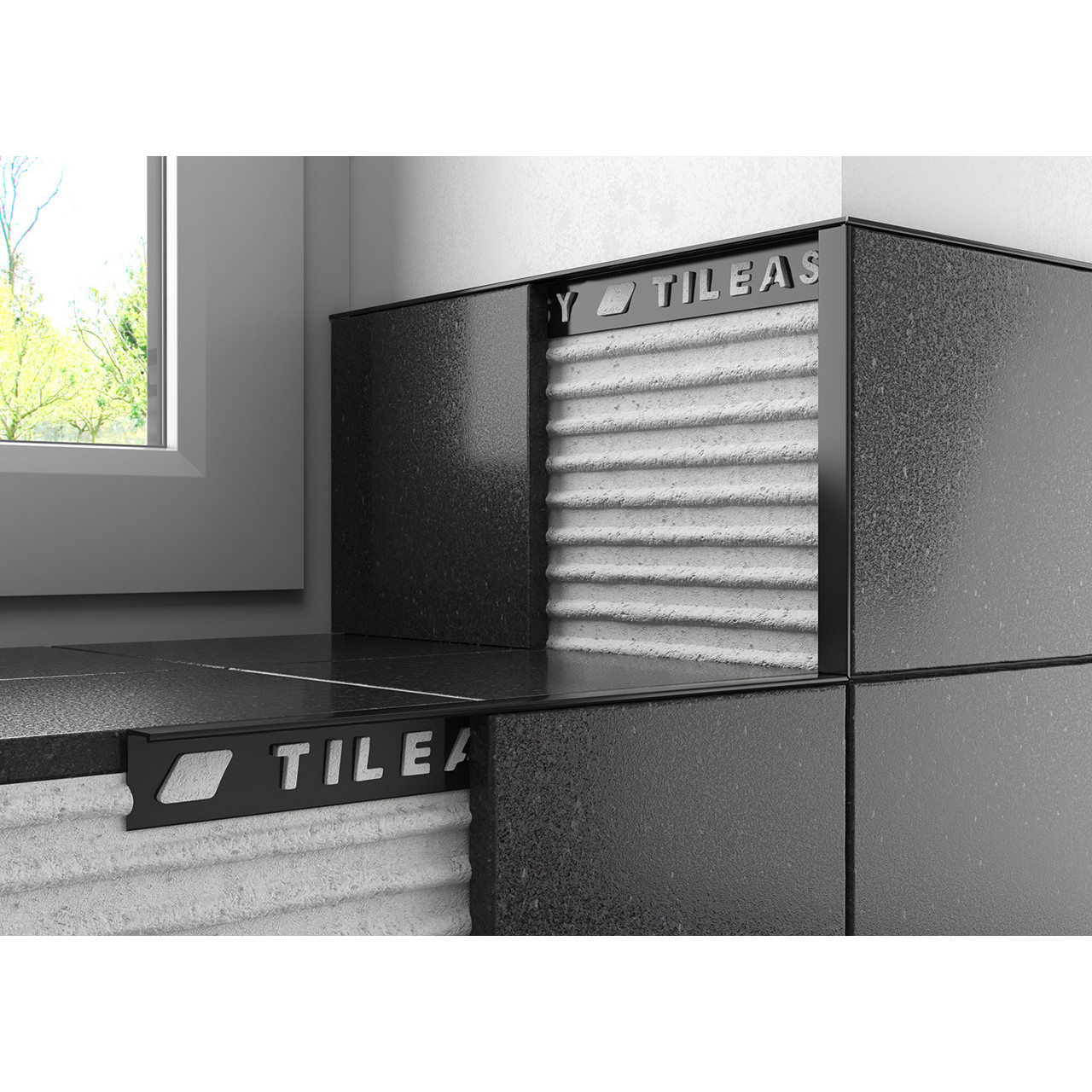

Tileasy 12mm Black Square Edge Metal Tile Trim Bat12 with dimensions 1280 X 1280

Tileasy 12mm Black Square Edge Metal Tile Trim Bat12 with dimensions 1280 X 1280Metal Tile Edging Trim Black – If you’re considering changing the task surface at some stages shortly, then it could make sense to await somewhat longer as the tops thickness might be totally different from the present one otherwise you realize that you prefer some other colour, design or fashion which will not match the tiles that you have got purchased (it has occurred repeatedly). With better technology is has become possible pay for special tile adhesives to put in new tiles on to existing tiles. It is worth mentioning that (where suitable) special attention will have to be settled about the existing background. Can your existing substrate contain the excess weight with the new covering? Does the perimeter edges be seen? Considering happy to see two levels of tiles protruding from your walls or possibly better to clear out the present layer? Will the additional thickness of tile become pushing outwards the electric powered outlets, causing problems while using socket’s screws being quite short? What regarding the electric cords about the sockets not had the capacity being stretched enough! All this must be taken in consideration ahead of you embark with your job. If you’re using the old floor tiles from the wall they make sure all of the adjacent areas are safeguarded by padded dust bed linens and that you might have full security gear on as the tiles can readily cut through bare skin. Dust face mask and goggles are an definite must.

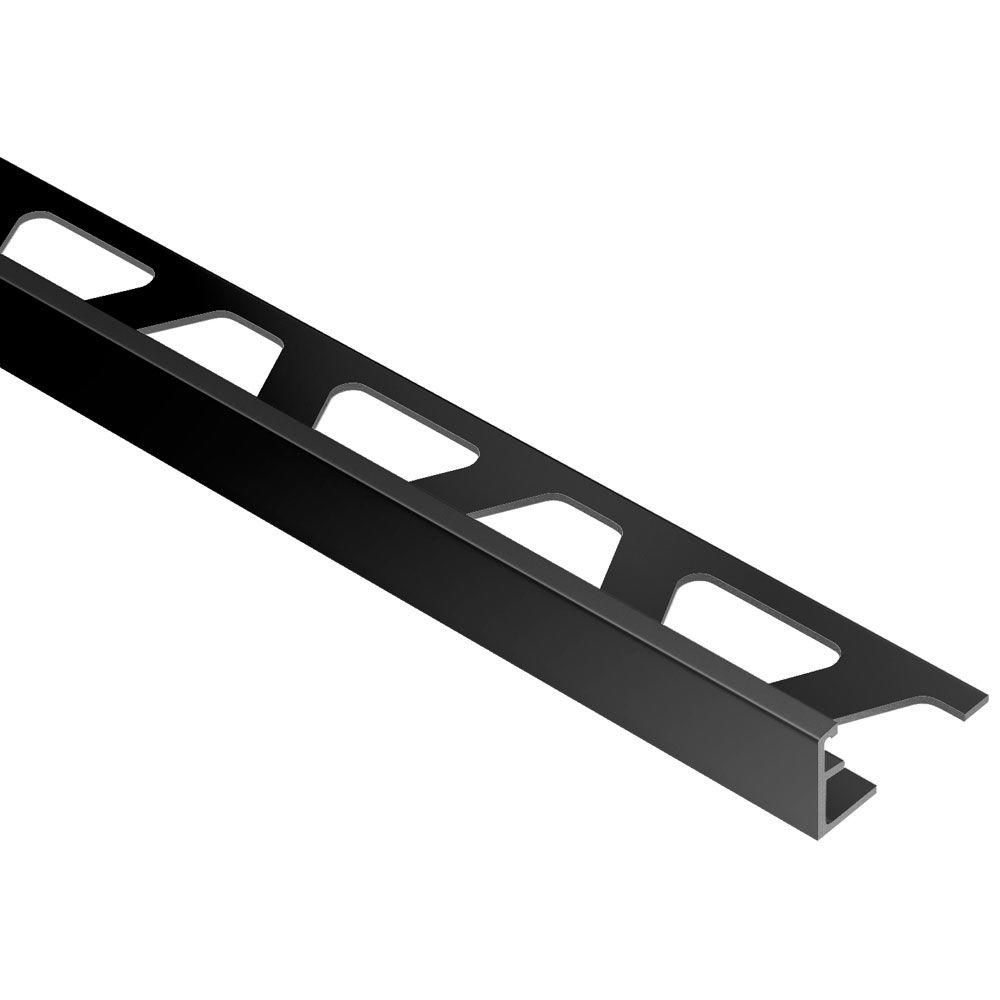

Schluter Jolly Bright Black Anodized Aluminum 316 In X 8 pertaining to size 1000 X 1000

Schluter Jolly Bright Black Anodized Aluminum 316 In X 8 pertaining to size 1000 X 1000Sizing inside the floor tiles Before you do just about anything else check to see should you have the right tiles, the right volume of tiles and when you’re using border tiles and inserts/decor tiles then look for size variations. This takes place often. If there are size variations you are going to have to take this into mind before selecting which intervals is more aesthetically right. What can happen is that you can have begun to tile the wall and get a 1. 5 mm joint, then you certainly squeeze border on the top and the border being to big, go beyond alignment through the rest with the floor tiles. Take your time. Try to visualize all of the tiles about the wall, as being a finished job, then it is possible to predict any potential problems and steer clear of them. Nearly prepared to floor tile Have a look about the tile’s packing to see if there are special tricks for spacing the tiles. Several tiles will need different joint sizes. If you use standard hard wall tiles you could use a couple of mm tile spacers naturally, should you use rustic tiles, your five – 10 mm coil spacers. All is relevant towards the design and dealing size with the tiles. Check for batch difference, try to open several bins and rehearse few floor tiles from each box. Look into the worktops having a spirit level (Ideally one that is certainly one hundred twenty cm or longer); find out if the tops are level, if not you might have to space inside the lowest section with tile spacers or possibly cardboard.

Schluter Rondec Bright Black Anodized Aluminum 516 In X 8 inside measurements 1000 X 1000

Schluter Rondec Bright Black Anodized Aluminum 516 In X 8 inside measurements 1000 X 1000If the base is definitely much beyond level from one end towards the various other, then you are going to have to allow a complete tile at the lowest level then draw an even lines at the top of this tile as well as any tiles that do unfit through the line down towards the worktop, will have to be trimmed to size by using a tile nippers or wet tile second hand cutter. Many times whenever you attempt to pull the road you will find how the electrical sockets are within the way. If this happens therefore instead utilizing one floor tile at the lowest point, employ two tiles, (one over the other and pull the level line at the top of the 2nd tile) that usually works. Do not forget to insert a floor tile spacer if you’re using any. In rare occasions you will be needing a laser level having a ongoing projected line or even a twisting laser level. This will perfectly go around the obstacles. What spreading trowel to use. The thickness with the adhesive need to be such that in the event the tile is at its final place, the adhesive must not squeeze out of your joints. Most times a scoop with 6 mm steps is ok as well as in general you need to use tiles of 10 — 20 cm square. Whenever mosaic is to be installed you will need a 3 mm notched trowel and when hand made floor tiles are being used, then both utilize 6 mm scoop and butter up a corner side with the tile, or make use of a 10 mm and previously mentioned to suit the tiles. Extra adhesive is going to be required in the event the tiles have a deep profile or studs than if a corner is soft. If there is adhesive squirting out of your tile joints, then make use of a thin flat screwdriver or possibly Stanley knife to the joint then utilize a wet cloth or sponge to wash the tiles. It is very important to not have the adhesive getting back in contact with normal stone (like marble) as it may stain it then deter from its nice look. Electric points. Undoubtedly you likely to have to slice around electric powered points (sockets, fuse spurs, cooker switches, light knobs, etc . ) Make sure that you just find out where the electric supply is definitely and SWITCH IT AWAY. You should be able to isolate your kitchen area electricity so that it is possible to still make use of other sockets around the house.

Schluter Rondec Graphite Anodized Aluminum 14 In X 8 Ft 2 for sizing 1000 X 1000

Schluter Rondec Graphite Anodized Aluminum 14 In X 8 Ft 2 for sizing 1000 X 1000Tiling tools. There are plenty of DIY tiling tools about the market that allow you to conduct tiling on a smaller funds. If you’re using thin ceramic tiles a tiling starter kit will help you. Here is everything you will be needing for a typical job. Tile Trims. In some occasions it is essential to set tile trims towards the floor tiles. An example of this is how two floor tiles meet by using an external point of view, where the tile edge will require protection from being chipped or possibly in the event the walls are not straight plus it is needed to have slashes at both extremities, or possibly in the event the tiles have zero glazed edges. If you want or require tile trim, be sure to utilize the right size ones to slip the thickness with the floor tile. Some tiles tend not to need tile trims because they get their edge glazed, others will require trims. If you’re painting them adjacent towards the tiles, you could utilize the trims only for the external angles where the floor tiles meet and just paint the unglazed edges on the top of the past tile.

Schluter Quadec Matte Black Textured Color Coated Aluminum 316 In X 8 Ft 2 12 In Metal Square Edge Tile Edging Trim regarding measurements 1000 X 1000

Schluter Quadec Matte Black Textured Color Coated Aluminum 316 In X 8 Ft 2 12 In Metal Square Edge Tile Edging Trim regarding measurements 1000 X 1000Windows. If one particular wall being tiled includes a window about it, get the center point with the window sill and measure while using floor tiles to see how large the end cutbacks are. If the end cutbacks are too small , cancel out the center examine half tile and recheck. Start while using best way of measuring to be able to achieve the top glimpse ( you are going to want a slice that is certainly greater than twenty mm). Attention must be put on not find yourself with opposite slashes too big (nearly full tile), as this will give you small cuts about the front straight with the window so because of this can provide you with issues with either cutting the tiles or even an even even worse problem with alignment in the event the straight edges are off straight. Also check to see in the event the home window sill is level. Oftentimes it isn’t and when honestly, that is the case it is possible to get the highest area and with regards to tile front side (between your worktop as well as the windowsill) start from there and once you’re prepared to tile the most notable with the sill, fill that level with adhesive. In the event the difference is to much, you may have to use two layers of tiles or make very good by incorporating plaster or concrete before tiling. Always look at the manufacturer’s instructions about the consumption and application. Silicone When the grout has dried you may apply the silicone sealant if needed. You can buy silicon ideal for general use, normally, this is with the “Acetoxy” type although if the tiles are made of natural rock then you certainly will be needing a silicon ideal for this (ask the supplier for any “Neutral Cure” silicone) as general silicon might stain some pebble. Silicone is a beast of the own. You will have to be quick and careful from it! It might be helpful should you purchase a silicon tool resource.