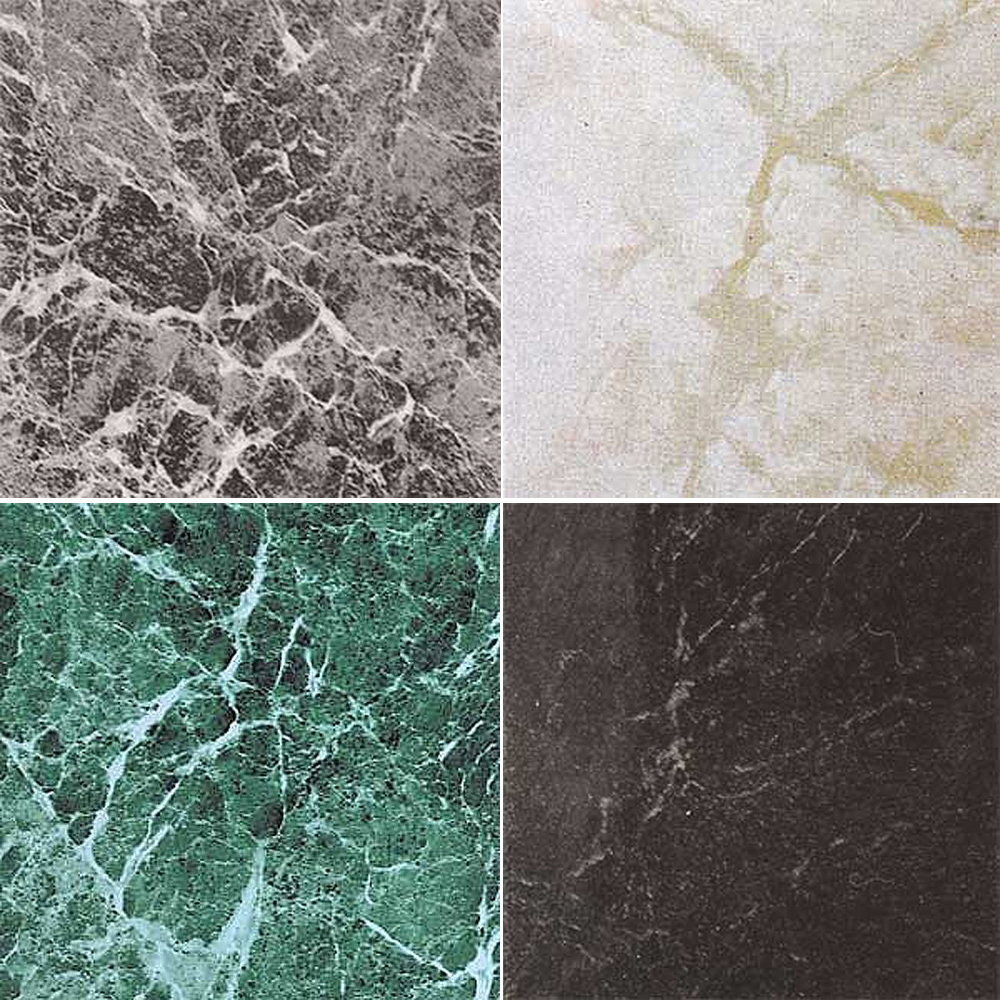

Colours Marble Effect Self Adhesive Vinyl Tile Pack 102m inside size 2825 X 2824

Colours Marble Effect Self Adhesive Vinyl Tile Pack 102m inside size 2825 X 2824Adhesive For Marble Floor Tiles – There a wide range of several types of porcelain tiles which, the handyman may apply to floors, walls and ceilings. One from the oldest types is ceramic tile — they’re baked clay and get used generally within the bath room for walls and surfaces. There are also plastic tiles that have been used mainly for walls and ceilings. Ceramic tiles, however , include moved out of your bathroom in other parts of the property. Contemporary homes usually have kitchen counter job tops and sometimes even living bedroom walls made of ceramic ceramic tile. These tiles can be used with special waterproof thorn to the suitable smooth area. No longer must you apply cable lath and cement to create the tiles available. Clear plastic tiles, which have gained in popularity because the end of World War II, are available in many different colorings, sizes and patterns. You will discover basically two types of plastic material tiles. The rigid types are made of polystyrene; the versatile tiles are usually made of vinyl fabric. Both are applied in to some extent the same manner, although some versatile tiles come already cemented. All that is important would be to soften the adhesive backs these self-adhesive tiles plus they then can be applied on the wall or simply floor.

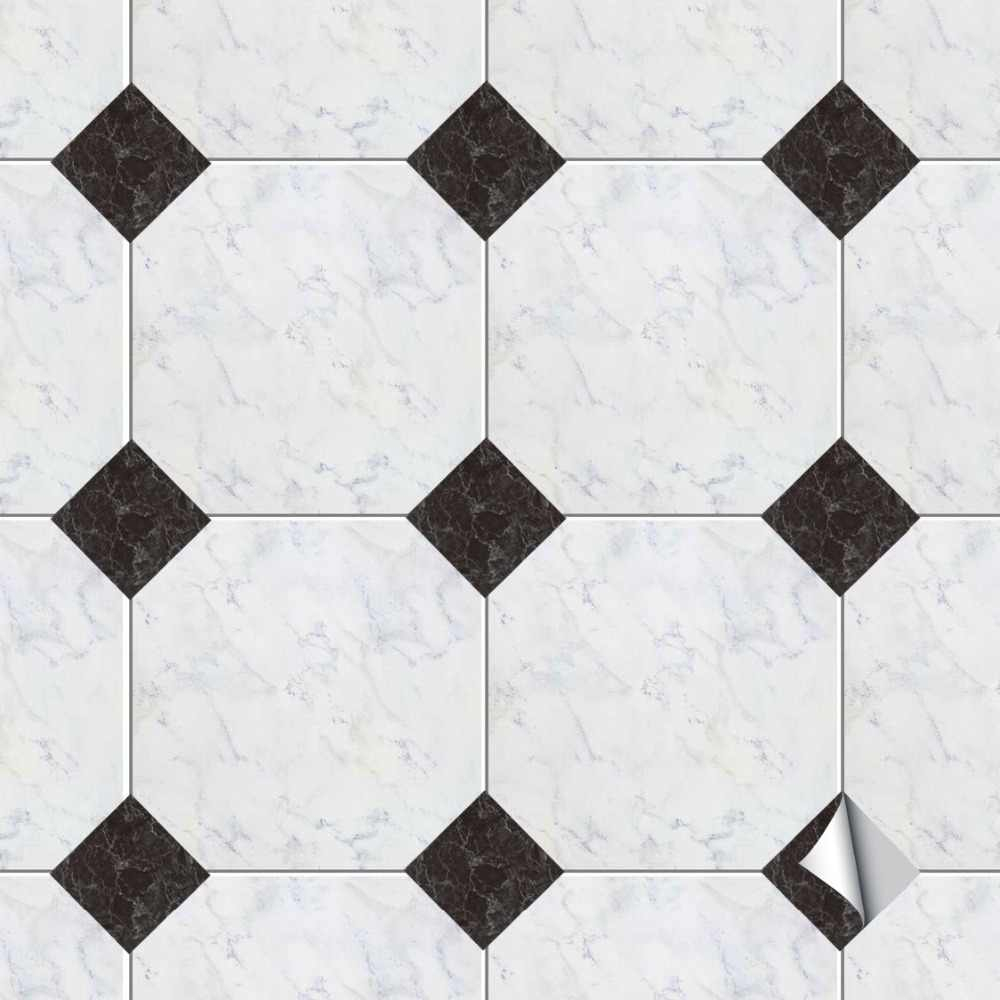

Details About Marble Vinyl Floor Tile 40 Pcs Self Adhesive Indoor Flooring Actual 12 X 12 intended for proportions 1000 X 1000

Details About Marble Vinyl Floor Tile 40 Pcs Self Adhesive Indoor Flooring Actual 12 X 12 intended for proportions 1000 X 1000Metal tiles of numerous kinds are likewise available. Probably the most recent developments is a great aluminum tile to which a ceramic coating is attached in a temperature of from 900° to 1000° F. It can be cut very easily and in many cases bent if needed. The tile is applied with mastic. Ceramic tile is probably the oldest building materials available. Its history dates back decades ago when it was first found that clay baked at great heat turns in a hard, durable materials that is both waterproof and fireproof. But tile is probably the most modern of materials, as well. It is easy for that average renovator to put in and will afford a very long time of constant, rugged make use of without deterioration. Real ceramic tile – that is certainly, tile manufactured from baked ceramic materials — is a permanent installation. Their colors never fade. Due to the durability along with the lack of any kind of upkeep or remodeling, genuine tile constitutes a significant economic climate. Today, ceramic tile exists on the homemaker in a amazing number of sizes, shapes, colorings, and textures. With a good water resistant adhesive, tile can be easily placed on walls, floors, and countertops. Technically, there’s 2 main divisions of ceramic tile: wall and ceramic tile. Wall porcelain tiles in popular use consist of 17/4″ square to 6″x9″ rectangles. They appear in either a huge glaze or possibly a matt glaze over that is a somewhat softer-looking area. Floor tiles go right from “dots” (11/32″ squares) to 9″ squares. Commonly used nominal sizes, though, would be the 2″ square, the 1″ block, along with the 1″x2″ rectangle. Surface tiles are often unglazed. Surface tiles can be separated in three subdivisions: Ceramic mosaics are less than six rectangular inches in facial area. Pavers are the types unglazed floor units measuring half a dozen square inches or more in facial surface. Quarries are supposed to resist especially severe circumstances of weather and have on. They possess a strong, dense body system that may withstand extremes in temperature.

Funlife Waterproof Bathroom Floor Tile Sticker Adhesive Pvc Marble Floor Decal Peelstick Sticker Non Slip Home Entrance Decor with measurements 1000 X 1000

Funlife Waterproof Bathroom Floor Tile Sticker Adhesive Pvc Marble Floor Decal Peelstick Sticker Non Slip Home Entrance Decor with measurements 1000 X 1000Here are quite obvious guidelines for installing ceramic floor and wall tiles. Virtually all common house surfaces which are true, level, clear of moisture and overseas matter are suitable for receiving ceramic tile. In any area suffering from vapor or water, the beds base area should be covered with two coats of primer, the other applied at right ways on the first. All joint parts and apertures, like the for bathroom fixtures, should be covered off with a waterproof adhesive tape. To begin tiling, install the end row first. Establish a quantity line for this. If the ground is not level, generate cuts within the bottom line of tiles. If that is completed, the most notable row from the wainscot is going to be level. Simply pull a pencil line above the glazed surface parallel towards the raised bars around the back side from the tile, take a common glass cutter and report the counter across the line. Then simply position the tile, glazed aspect up, on the nail and press on either aspect from the scored line. The tile will part on traget down the road. For special slicing, like around fixtures, make use of pliers to nip away small chunks from the ceramic tile. Then smooth the counter which has a Carbo-rundum stone. Tiles inside the bottom row should be “buttered’ individually with a small few drops of adhesive and then pressed up against the wall. Don’t put on a lot adhesive; it may ooze out from the joints between tiles. Following setting the initial line, spread a thin layer of backing over several feet square which has a saw-tooth trowel. Press the tiles firmly into place with a twisting motion on the hand. Spacing bars around the edges of wall ceramic tile can keep the pieces a uniform distance apart. When a wall may be tiled, allow it set for a day possibly even the volatile elements inside the adhesive can escape. Then simply soak the joints between porcelain tiles with a wet sponge by least four times by five-minute intervals. A gallon of water is sufficient for about 50 feet square of tile-work. Soaking – thorough sitting – is conducted so your porcelain tiles will not likely draw water in the fine cement, called binding material, accustomed to fill the areas bewteen barefoot and shoes. Commercial grout can be described as fine white powder. Blend it with water towards the consistency of heavy cream. Let it indicate quarter-hour and remix. The mixture could be applied on the tile joint parts with a sponge, a squeegee or yourself with a couple of rubber gloves. Fill sore joints completely. Going over the work while using end from the handle of your toothbrush gives it a specialist finish. It can help to pressure the grout into the joint parts, too. Cleaning is straightforward. A humid sponge or cloth will certainly get rid of the excess grout in the face from the tile. A dried cloth should be used for gloss. But before the final polishing, each of the grouted joints should be moist down with a sponge repeatedly within the next four to five days, so they will set properly. Polished porcelain tiles is defined the identical way way because wall tile. The surface need to first be in good shape, organization, perfectly smooth and devoid of moisture and foreign subject. Floor tile – small unglazed units – come pasted on to paper sheets gauging l’x2′.

Funlife Waterproof Bathroom Floor Tile Sticker Adhesive Pvc Marble Floor Decal Peelstick Sticker Non Slip Home Entrance Decor within sizing 1000 X 1000

Funlife Waterproof Bathroom Floor Tile Sticker Adhesive Pvc Marble Floor Decal Peelstick Sticker Non Slip Home Entrance Decor within sizing 1000 X 1000Sheets from the floor tile are pressed into the backing spread around the floor, while using papered side uppermost. Let the ceramic tile set an hour or so. Wet the paper slightly with a soaked sponge and pull it from the tile. At this time, the thorn is still pliant in order to re-align individual tiles if needed. When you have to walk over the floor right now, achieve this up to speed or cardboard boxes so your weight is going to be more evenly distributed. The floor, just as the wall membrane, should be in a position to set to get a day before grouting. Although ceramic tile, that has little absorbency, doesn’t have to get soaked ahead of grouting. The grout mix here is different. It should include one part waterproof Portland cement and one component finely screened sand. At least amount of water needs to be utilized in mixing – sufficient for workability. Spread this type of mixture over the floor and work it into the joint parts with a squeegee. Joints needs to be completely filled. All extra mortar should be removed ahead of it begins to harden. Make use of a burlap cloth to start with then a damp cloth. If necessary, discuss it repeatedly until almost all traces of grout have passed away. Then polish with a dried cloth. The floor must be cured. Cover it and look after all traffic off this for around 3 days. If it is necessary just to walk about it in that time, put down boards. Excellent installations of ceramic ceramic tile with the homemaker happen to be built on bathroom walls, surfaces and countertops; in house laundries the place where a definitely watertight surface is required; in your kitchen, including extensive countertops and splash-backs; and in game bedrooms the place where a durable yet once and for all decorative finish is wanted. Tile is used more and more as surfacing for living room floors and within the living area. The most recent craze is the use of colorful ceramic tile around the exterior of homes the place where a ornamental yet weatherproof paneling is usually desired, like the exterior looking over the outdoor terrace. Balconies, of course , have for ages been made of ceramic tile – quarry tile which created from natural ceramic products. Quarry comes in shades of purple, chocolate and buff. Entranceways are usually popular sites for scrape tile. Smaller decorative uses of tile around the house include: fireplace fronts, hearths, windowsills where plants happen to be set, table tops, areas of room dividers, rad tops, stairways, and cabinets.

Funlife Self Adhesive Diagonal Floor Tile Seam Stickers within size 1000 X 1000

Funlife Self Adhesive Diagonal Floor Tile Seam Stickers within size 1000 X 1000All tile created from healthy ceramic materials is easy to keep clean. A detergent ideal both floor and wall membrane. For floors, the detergent solution should stay on the area a couple of minutes before mopping. Get rid of the ground and wall dried with a soft cloth. Many soap leaves a gross film over tile. This kind of film retains dirt and may make the ground slippery. In cases where such a condition already is present it can be remedied with a rinse of business scouring powder or simply kerosene. Waxes, plastic comes to an end, polishes, emulsions, nonslip films along with the like should never be required. Pebble tiles are for sale to be used on any wall surface that is properly prepared. The pebble tiles are installed in the method somewhat the same as ceramic tiles. Right here is the technique of handling pebble, in this instance Vermont Pavonazzo. Even though popular in 12″ verger for floor covering, vinyl porcelain tiles within the 17/4″ squares to be used on walls has lowered in popularity within the last several years. They have given way nearly exclusively to ceramic ceramic tile which was formerly a amount of affluence for their then simply expensive. Now, fired clay-based, or ceramic tiles, are staying imported and sold at rates similar to that of vinyl. Also at comparable prices, elements weigh for ceramic intended for wall applications. Ceramic ceramic tile features a sheen and shine that can’t be matched simply by vinyl. They are hard, nevertheless , and in places where furniture might bump contrary to the tile, vinyl fabric may be preferred. The strength of vinyl is, naturally , excellent to use like a flooring. Vinyl tile will work for utilization in bathrooms, also it flushes easily. For use in kitchens, 1 precaution should be considered. In cases where vinyl tile is utilized lurking behind the kitchen range there could be the prospect of discoloration soon enough. Vinyl flooring is not fireproof as well as the heat from the range might affect it.