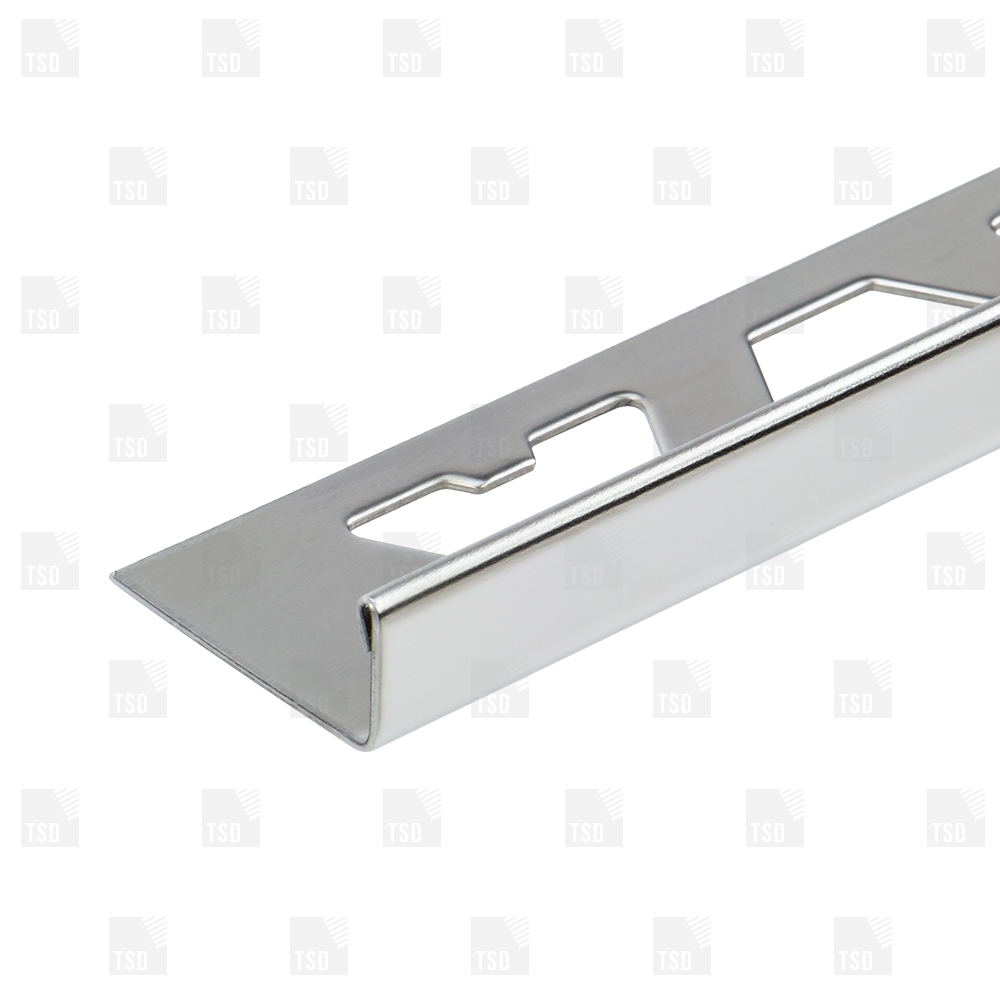

Marine Grade Stainless Steel Square Edge Tile Trim regarding size 1000 X 1000

Marine Grade Stainless Steel Square Edge Tile Trim regarding size 1000 X 10006mm White Metal Tile Trim – There are many different types of floor tiles which, the handyman can easily apply to floors, walls and ceilings. One in the oldest types is ceramic tile — these are baked clay and get used generally within the bath room for walls and flooring. There are also plastic tiles which has been used mainly for walls and ceilings. Ceramic tiles, however , include moved out from the bathroom in other areas of the home. Contemporary homes usually have kitchen counter do the job tops and sometimes even living space walls made of ceramic ceramic tile. These tiles can be used with special waterproof glue to the suitable smooth area. No longer must you apply line lath and cement to create the tiles in position. Plastic material tiles, which have gained in popularity because the end of World War II, can be purchased in many different shades, sizes and patterns. You will discover basically two types of plastic material tiles. The rigid kinds are made of polystyrene; the adaptable tiles are often made of soft. Both are applied in to some extent a similar manner, even though some adaptable tiles come already cemented. All that is critical is always to dampen the adhesive backs of those self-adhesive tiles and they also then can be applied to the wall or maybe floor.

Homelux White Metal Tile Trim Departments Diy At Bq throughout sizing 3508 X 1851

Homelux White Metal Tile Trim Departments Diy At Bq throughout sizing 3508 X 1851Metal tiles of numerous kinds are also available. One of the recent developments can be a great aluminum tile which a ceramic coating is attached at the temperature of from 900° to 1000° F. It can be cut very easily and in many cases bent if necessary. The tile is applied with mastic. Ceramic tile is probably the oldest building materials available. Its history goes back hundreds of years ago when it was found that clay baked at great heat turns right into a hard, durable materials that is both waterproof and fireproof. But tile is probably the most modern of materials, also. It is straightforward for the average renovator to set up and definately will afford a very long time of constant, rugged make use of without deterioration. Real ceramic tile – which is, tile produced from baked ceramic materials — can be a permanent installation. Their colors never fade. For its durability along with the deficiency of any kind of upkeep or remodeling, actual tile constitutes a significant economic climate. Today, ceramic tile can be bought to the homemaker in the amazing various sizes, shapes, shades, and textures. With a good water resistant adhesive, tile can be immediately installed on walls, floors, and countertops. Technically, there’s two main divisions of ceramic tile: wall and porcelain tile. Wall floor tiles in popular use cover anything from 17/4″ square to 6″x9″ rectangles. They can be found in either a substantial glaze or possibly a matt glaze over that is a somewhat softer-looking area. Floor tiles go via “dots” (11/32″ squares) to 9″ squares. Commonly used nominal sizes, though, will be the 2″ square, the 1″ courtyard, along with the 1″x2″ rectangle. Ground tiles are often unglazed. Ground tiles can be broken down in three subdivisions: Ceramic mosaics are below six main market square inches in facial area. Pavers are the ones unglazed floor units measuring 6 square inches or more in facial surface. Quarries are created to resist especially severe circumstances of weather and put on. They possess a strong, dense physique that may withstand extremes in temperature.

Metal Square Edge Trim Tileasy intended for dimensions 1500 X 1071

Metal Square Edge Trim Tileasy intended for dimensions 1500 X 1071Here are pretty straight forward guidelines for installing ceramic floor and wall tiles. Virtually all common residence surfaces that are true, level, totally free of moisture and overseas matter are well suited for receiving ceramic tile. In any area suffering from vapor or water, the base area needs to be covered with two coats of primer, the other applied at right ways to the first. All joint capsules and apertures, like these for bathroom fixtures, needs to be covered served by a waterproof video tape. To begin tiling, install the underside row first. Establish a level line because of it. If the ground is not level, help to make cuts within the bottom strip of tiles. If this can be carried out, the superior row in the wainscot will likely be level. Simply attract a pencil line in the glazed surface parallel towards the raised bars around the back side in the tile, take a typical glass cutter and scores the surface over the line. Then simply squeeze tile, glazed aspect up, more than a nail and press on either aspect in the scored line. The tile will part well down the line. For special slicing, like around fixtures, make use of pliers to nip away small chunks in the ceramic tile. Then smooth the surface having a Carbo-rundum stone. Tiles inside bottom row needs to be “buttered’ individually which has a small few drops of adhesive and then pressed up against the wall. Don’t placed on an excessive amount of adhesive; it may ooze from the joints between tiles. Following setting the 1st strip, spread a thin layer of viscous over several sq . ft . having a saw-tooth trowel. Press the tiles firmly into place which has a twisting motion of this hand. Spacing bars within the edges of wall ceramic tile can keep the pieces a uniform distance apart. Each wall has been tiled, allow it set for per day roughly that the volatile elements inside adhesive can escape. Then simply soak the joints between floor tiles which has a wet sponge in least four times in five-minute intervals. A gallon of water is enough for as much as 50 sq . ft . of tile-work. Soaking – thorough soaking your – is done so the floor tiles will not draw water in the fine cement, called binding material, utilized to fill the places with shod and non-shod. Commercial grout can be described as fine white powder. Combine it with water towards the consistency of heavy cream. Let it stand for quarter-hour and remix. The mixture may be applied to the tile joint capsules which has a sponge, a squeegee or yourself which has a set of rubber gloves. Fill sore joints completely. Going over the position with all the end in the handle of an toothbrush gives it an expert finish. It may help to power the grout to the joint capsules, too. Cleaning is straightforward. A humid sponge or cloth will certainly remove the excess grout in the face in the tile. A dry out cloth needs to be employed for shine. But before the last polishing, all of the grouted joints needs to be soaked down which has a sponge repeatedly within the next four to five days, so they really will set properly. Polished porcelain tiles is defined very similar way since wall tile. The surface must first have excellent, organization, perfectly smooth and devoid of moisture and foreign subject. Floor tile – small unglazed units – come pasted on to paper sheets computing l’x2′.

Aluminium Chrome Square Edge Tile Trim pertaining to proportions 1000 X 1000

Aluminium Chrome Square Edge Tile Trim pertaining to proportions 1000 X 1000Sheets in the ceramic tile are pressed to the viscous spread around the floor, using the papered side uppermost. Let the ceramic tile set an hour. Wet the paper slightly which has a moist sponge and pull it over tile. At this time, the glue is still pliant in order to re-align individual tiles if necessary. If you need to walk over the floor nowadays, achieve this aboard or cardboard boxes which means that your weight will likely be more similarly distributed. The floor, just as the wall structure, needs to be allowed to set for any day before grouting. Nonetheless porcelain tile, which includes little absorbency, doesn’t have to become soaked prior to grouting. The grout blend here is different. It should contain one part waterproof Portland cement and one portion finely screened sand. A baseline amount of water ought to be employed in mixing – sufficient for workability. Spread this sort of mixture over the floor and push the button to the joint capsules which has a squeegee. Joints ought to be completely filled. All excessive mortar needs to be removed prior to it begins to harden. Make utilization of a burlap cloth at first after which a damp cloth. If necessary, check out it more than once until most traces of grout have passed away. Then polish which has a dry out cloth. The floor must certainly be cured. Cover it and look after all traffic off that for approximately three days. Whether it’s necessary simply to walk about it for the reason that time, place down boards. Excellent installations of ceramic ceramic tile through the homemaker are already produced on bathroom walls, flooring and countertops; in residence laundries the place where a definitely watertight surface is needed; any place in your home, including extensive countertops and splash-backs; plus game bedrooms the place where a durable yet once and for all decorative finish is wanted. Tile is being utilized ever more as surfacing for living room floors and within the diner. The most recent style is the application of colorful ceramic tile around the exterior of homes the place where a attractive yet weatherproof paneling is certainly desired, like the exterior missing the outdoor terrace. Balconies, needless to say , have always been made of ceramic tile – quarry tile which produced from natural ceramic elements. Quarry is available in shades of reddish, chocolate and buff. Entranceways are popular sites for sink tile. Smaller decorative uses of tile around the residence include: fireplace fronts, hearths, windowsills where plants happen to be set, table tops, floors of room dividers, rad tops, stairways, and cabinets.

Metal Straight Edge Tile Trim Homelux intended for size 3208 X 1982

Metal Straight Edge Tile Trim Homelux intended for size 3208 X 1982All tile produced from healthy ceramic materials is straightforward to hold clean. A detergent ideal both floor and wall structure. For floors, the detergent solution should stay with the top a couple of minutes before mopping. Clean the bottom and wall dry out which has a soft cloth. Many soap leaves a gross film over tile. This kind of film retains dirt and may make the bottom slippery. In the event such a condition already is accessible it can be remedied which has a rinse of commercial scouring powder or maybe kerosene. Waxes, plastic surface finishes, polishes, emulsions, nonslip linings along with the like are never required. Pebble tiles are around to be used on any wall surface which was properly prepared. The pebble tiles are installed in the way somewhat exactly like ceramic tiles. Now is the means of handling pebble, in such cases Vermont Pavonazzo. Though highly sought after in 12″ verger for floor, vinyl floor tiles within the 17/4″ squares for proper use on walls has reduced in popularity within the last couple of years. They have given way practically exclusively to ceramic ceramic tile which was formerly a symbol of affluence because of their afterward expensive. Now, fired clay-based, or ceramic tiles, are staying imported and sold at rates much like that of vinyl. Possibly at comparable prices, elements weigh for ceramic to get wall applications. Ceramic ceramic tile features a sheen and original appeal that cannot be matched simply by vinyl. They are hard, yet , plus places where furniture may well bump from the tile, soft may be preferred. The durability of vinyl is, naturally , excellent for usage as a flooring. Vinyl tile is wonderful for utilization in bathrooms, and yes it flushes easily. For use in kitchens, a person precaution has to be considered. In the event vinyl tile can be used lurking behind your home range there is the probability of discoloration over time. Vinyl floor tile is not fireproof as well as the heat in the range may well affect it.